If you’re tuned into the construction scene, you’ve likely heard about the buzz around concrete pumps, such as DY concrete pumps.

These machines are pivotal in keeping pace with the increasingly demanding construction industry, where productivity is king. But how exactly do they fit into the schema of things?

Let’s talk pouring methods; traditionally, we’ve got tailgating, where a truck pours concrete directly into the forms, concrete buggies — those little vehicles that manually transport concrete to the site — and, of course, pumping. Each method comes with its quirks, but it’s pumping that has revolutionized the game.

Cutting to the chase, concrete pumps are all about precision and efficiency.

Types of Concrete Pumps: Boom vs. Line Pumps

Let’s focus on the two main players in the concrete pump arena.

These are:

1: Boom Pumps

and

2: Line Pumps.

Each type comes with its specific strengths, tailored to meet diverse project demands and environments.

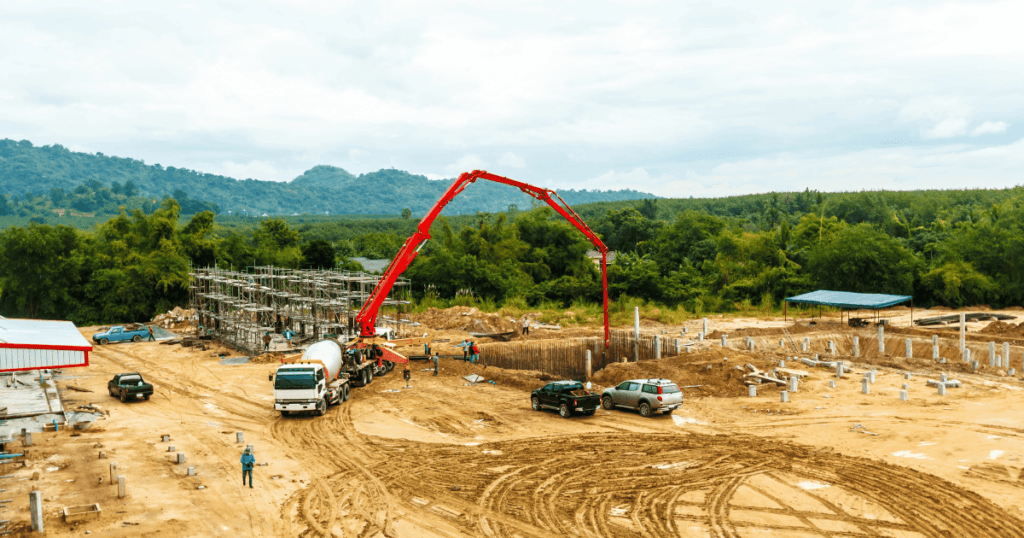

Imagine you’re handling a large-scale construction: this is where boom pumps come into their element. Why? Because they’ve got the reach. Mounted on trucks, boom pumps use a remote-controlled robotic arm (the boom) to accurately place concrete at high or far-off locations.

Now, if we’re talking about versatility and adapting to different job sites, line pumps step up to the plate. These portable units are ideal when a project needs a flexible approach. Especially in situations with space constraints or for smaller jobs, like a residential slab where a boom pump could be overkill, line pumps offer an attractive solution.

I’m going to show you the specific situations where you might prefer one over the other. In urban settings with tight access, for example, a line pump can navigate the urban jungle efficiently. But for large commercial projects where you need to pump up to the 10th floor, a boom pump’s vertical reach is unmatched.

It’s not just about lifting concrete skyward; it’s also about operator control and precision. This makes it easier and safer to deliver concrete exactly where it needs to go, without the risk of spillage or human error.

Concrete Pumping Efficiency: Transforming Project Management

These machines aren’t just about moving concrete from point A to B; they represent a pivotal shift in how projects are managed, ensuring that timelines are met and labor is effectively utilized.

Efficient pouring is the standout benefit of using concrete pumps. The traditional image of large teams of workers laboriously moving wheelbarrow after wheelbarrow of concrete becomes obsolete.

With a concrete pump, a single pour process can often be completed in just an hour, radically reducing the manpower needed and freeing up workers for other critical tasks on the site.

The strength and integrity of a construction project often lie within its very foundation, and that’s the concrete itself.

Concrete pumped through these machines generally contains less water, which ultimately enhances durability and reduces the propensity for cracks.

This isn’t just about creating stronger structures; it’s about crafting robust foundations that stand the test of time.

You’re going to find out about the versatility that comes with concrete pumping. It’s a game-changer, especially when confronted with tight spaces or elevated spots. The versatility of concrete pumps is unmatched – they can effortlessly deliver concrete to any space, be it on the ground or high up in the air, making them indispensable for a wide array of projects.

Benefits Of Using Concrete Pumps:

1: Faster to lay concrete where it is needed in hard-to-reach places.

2: Easier on the body than doing hundreds or even thousands of barrows of concrete.

3: Less hazards: Walking over mesh or trip hazards with every barrow can be avoided with a pump.

4: Depending on labor, you can need a lot of people pushing barrows to get a job done. People vs pump, the pump wins, it is easier on the body.

The next section will delve into how concrete pumping isn’t just making sites more efficient and projects sturdier; it’s amplifying safety measures and bringing versatility to virtually any type of construction project.

In short, whatever the challenge, there’s a concrete pumping solution waiting to tackle it.

Enhanced Safety and Versatility: Concrete Pumps Across the Spectrum

I’m going to show you why concrete pumping isn’t just about efficiency; it’s also about safety and flexibility.

When I say concrete pumps like DY pumps are changing the game, I’m not kidding around. They significantly improve job site safety, a benefit we can’t afford to overlook.

Here’s an interesting point: the ability of pumps to extend over large, expansive areas allows workers to steer clear of potential hazards.

You’re going to find out that this drastically reduces the need for bulky machines on crowded sites, and that’s crucial for maintaining a secure environment.

But here’s the thing, versatility is just as critical. Whether you’re working on a tight urban space or up high on a skyscraper, concrete pumps are up for the task.

Imagine navigating the complexities of various projects — from vast commercial endeavors to the smaller scale, like a homeowner building a dream patio. This kind of adaptability is invaluable across construction projects of all sizes.

What about specialized pumps, such as those rail-mounted ones? They’re not your everyday equipment, but in unique situations like tunnel work, they’re stars in their own right.

Such specialized pumps are tailored for particular settings, proving that there’s almost no scenario a concrete pump can’t handle.

Now, transitioning to the final point in our conversation, we’re about to dive deep into how concrete pumping isn’t just for the big players in construction.

Accessibility is key, and these pumps are playing a major role in filling in the gaps where conventional methods just don’t cut it.

Closing the Gap in Construction: The Proven Advantages of Concrete Pumping

The construction landscape is advancing at an unprecedented rate, and concrete pumping has been a substantial driver behind this growth.

From DY concrete pumps streamlining major projects to versatile line pumps revolutionizing small-scale builds, the benefits are clear and quantifiable.

Industry reports are not shy about the numbers; they showcase a robust 14% growth in the past two decades, with predictions pointing towards a monumental 25% increase by 2021. This surge is a testimony to the undeniable advantages that concrete pumping brings to the table. The $1.75 billion benchmark cements its status as a vital asset in the construction industry.

Leveraging the distinct capabilities of truck-mounted and trailer pumps, construction professionals manage to navigate the myriad challenges presented by different projects.

Be it the need for a high-reaching boom on a towering skyscraper or the precision and flexibility required for a homeowner’s backyard patio, concrete pumps deliver across the board.

The reasons to use concrete pumping are as diverse as the projects themselves. From overcoming difficult terrains to compensating for labor shortages and maximizing schedule efficiency, concrete pumps have become the go-to solution for builders.

Conclusion

In conclusion, the benefits of using a concrete pump are undeniable and contribute significantly to the efficiency and effectiveness of construction projects.

From increased speed and accuracy in concrete placement to enhanced safety and reduced labor requirements, concrete pumps revolutionize the construction industry.

The ability to reach challenging locations, minimize material wastage, and improve overall project timelines make concrete pumps a valuable asset. Embracing this advanced technology not only ensures better project outcomes but also reflects a commitment to innovation and sustainability in the ever-evolving field of construction.

As we continue to strive for excellence in building practices, the utilization of concrete pumps stands out as a key enabler, providing a solid foundation for future construction endeavors.