If you need to buy concrete dye or concrete dye powder, buying this online is an easy and straightforward process, and to be honest it’s just like buying anything else.

However, it can make things even easier if you already have a concrete dye color in mind.

If you need to buy concrete dye or concrete dye powder you’ll be glad to know buying it online is a safe, easy, and fast process.

If you already know what color you are after this makes the process even faster again! and if not, there are loads of colors and ideas to look through and I’m sure there is something there for you.

“as an Amazon Associate, I may earn from qualified purchases”

Best Concrete Dye

Uses Of Iron Oxide ( Concrete Dye )

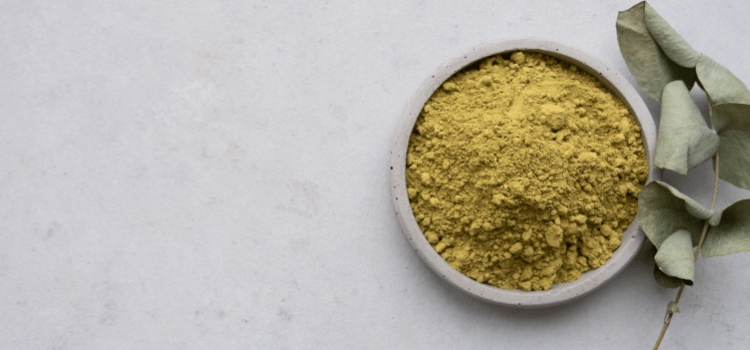

Iron oxide, which is also called ferric oxide or concrete dye, is an inorganic compound having the chemical formula Fe2O3.

It is one of the 3 major oxides of iron, and the remaining two being iron(II) oxide (FeO), which is the rare iron and (II, and III) oxide (Fe3O4), also naturally takes place as the mineral magnetite.

Since the mineral is referred to as hematite, Fe2O3 is iron’s primary source for the steel industry and is readily attacked by acids.

Often, iron oxide can be referred to as rust. This label is useful to some extent because rust shares many properties and has the same composition. However, in chemistry, rust is considered an ill-defined material, which can be described as Hydrous ferric oxide

Uses of Iron Oxide

- Iron oxide powder – also called cement powder or concrete powder is a widely used inorganic pigment with the characteristics of high stain colouring power, and scores high with good weather resistance.

- It can be used for cement concrete, building materials, all kinds of coatings (powder coating, rigid coating, water-based paint coating), toy paint, decorative paint, furniture paint, electrophoresis paint and enamel paint, etc.

- Cement color used for various indoor and outdoor colored concrete surfaces, such as walls, floors ceilings, pillars, porches, pavements, parking lots, stairs, stations, etc

- Iron oxide pigment black use in various building ceramics and glazed ceramics bricks, floor tiles, roof tiles,panel, terrazzo,mosaic tiles, people marble making

- Iron oxide coloring of plastic products, Such as thermosetting plastics and thermoplastics, and coloring of rubber products, like car inner tubes, fly inner tube, bicycle Inner tubes.

- Concrete color iron oxide coloring of paint and coating, such as powder coating, roll-up coating, automobile paint, ship paint, baking paint, floor paint, milk glue paint, road marking paint, printing paste, etc.

- Concrete color iron oxide use in various building ceramics and glazed ceramics bricks, floor tiles, roof tiles, panel, mosaic tiles, people marble making

Types Of Concrete Dye

To buy concrete dye online is all very well and good, if the job suits the budget and you know what you are looking for when it comes to the different pros and cons to different concrete dyes.

Certain concrete dyes are more suited for all weather conditions and have UV protection properties in them.

The dye will hold its color for longer and the dyes color will often be more accented in better more expensive concrete dyes, compared to cheap concrete dyes that may not provide any UV protection at all..

How To Dye Concrete

There should be instructions on every pack of concrete dye you bye.

However if there is no instructions, there is no harm in making up the mixture to your liking.

Just keep in mind a few pointers…

How To Dye Concrete

- How much cement are you using altogether? you will normally need about 2.5 pounds per 60 pound sack of concrete. This will make approximately 1 square yard of concrete at 4 inches thick.

- Mix your aggregates, sand and cement first before placing in your concrete dye.

- The concrete mix will look darker at first. After the curing stage the color will dry a few shades lighter.

- Once your concrete has cured properly, ( About 2 – 4 weeks ) seal your dyed concrete with concrete sealant.

How To Maintain Dyed Concrete

All dyed concrete should be sealed.

Sealing your concrete protects your concretes finish, prolongs the durability of your concrete and the concretes color.

Concrete sealant can be brushed on with a standard paint brush, or for larger jobs like driveways or patios a broom is great.

A paint roller or air sprayer can be used as well.

Concrete driveways, patios, footpaths should be at least 2 layers thick.

Allow each coat of sealant to dry before recoating. Drying times will be different from day to day, and from job to job.

Why Buy Concrete Dye?

To buy concrete dye is very inexpensive, and can be added very simply to your concrete mix. It can make your plain-looking concrete stand out and look more like a feature piece. People love dyed concrete and dyed concrete patios or other dyed concrete projects are always great conversation starters.