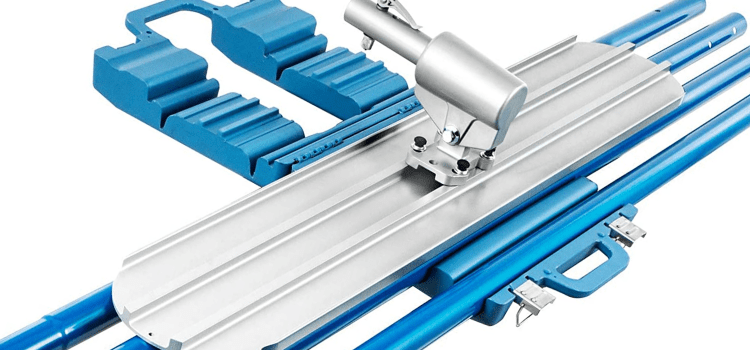

A plate compactor is an electric or motorized tool that compacts ground materials like stones, soil, asphalt, etc, and is vital in achieving the highest quality of workmanship in driveways, house and garage floors, paths, laneways, roads, ot anything else that needs to rest on a solid foundation.

A plate compactor can also be used to compact lawn, dirt, and sand.

Why You Should Use A Plate Compactor?

These are the main points why you should use a plate compactor before concreting.

What To Look For When Buying A Plate Compacter

Contrary to what many may think, the weight and motor size of a plate compactor do not mean a better result of compacted ground.

A plate compactor’s power is measured in pounds per square inch, and the term used for this is called centrifugal force.

What is centrifugal force?

Centrifugal force is the outward force on a mass when it is rotated.

Examples:

- A ball on the end of a string that is being twirled around.

- The outward motion you feel when turning a car at with speed.

In an inertial frame, there is no outward acceleration since the system is not rotating. Although weight and motor size are important, centrifugal force is of utmost importance.

I have done a small comparison comparing these 4 brands of compactors, and although they are all popular and quality compactors, they don’t all share the same qualities.

Plate Compactor Comparison

Compaction force in Lbs per square foot.

- Built Hard plate compactor…6.5HP motor…2500 lbs compaction force.

- 6HP Tomahawk plate compactor…6HP motor…3000 lbs compaction force

- North Star plate compactor…5.5HP motor…3968 lbs compaction force

- Tomahawk plate compactor 5.5HP motor…3000 lbs compaction force

The North Star Plate Compactor - 1st Place

Out of the four plate compactors here, I would have to recommend the North Star plate compactor.

Great value and great specs, this plate compactor has good reviews and has a customer average review start rating of 4.3 stars.

About this item

- 3968 lbs. of compacting force

- 65–82 feet per minute travel speed

- 21 1/2in. x 16 5/16in. compacting plate

- 6400 vibrations per minute

- 163cc Honda GX160 OHV engine with cast iron cylinder liner

Tips When Using A Plate Compactor

There is not too much to learn when it comes to using a compactor, although there are a few tips that can help.

1– Spray the ground to dampen the material you are compacting. A little amount of water helps the material you are compacting to compact and find its resting spot.

Too much water and the compactor will sink and not vibrate in a forward motion.

2 – If you are working next to edges where the ground can break off and/or the compactor can slip into. If we compact about 400mm away from any outside footing edge you will minimize the compactor slipping in or blowing off the edge.

On the next round of compacting, you can then go 350mm away from the edge, compacting 50mm more each time you pass with the compactor. By doing this the majority of the compactor is always sitting on already compacted ground.

By compacting like this, you can get compaction closer to any edge without damaging the foundation and/or the compactor.

3 – If your foundation needs to be built up more than a height of 200mm it is always advised to compact foundational material in layers of 150mm.

Although you will not notice too much from the look and feel by foot, compacting in layers of 150mm will ensure maximum compaction.

Although a compactor may vary in strength, weight, and power the 150mm rule, is a good rule to follow.

Summarizing a Plate Compactor?

Overall, a plate compactor is used to harden and compact the ground in order to provide a solid foundation.

The amount of centrifugal force will determine the compaction of your material.

Remember, weight and engine size are not everything when it comes to plate compactors, and centrifugal force is more important.