So what is concrete strength and why do we need to get it right?

One of the most important properties of concrete is its strength, which refers to its ability to withstand external forces without breaking or crumbling.

In this blog, we will discuss concrete strength in more detail.

Concrete is one of the most commonly used building materials in the world. It is a mixture of cement, water, aggregates, and sometimes additives.

What Is Concrete Strength?

Concrete strength is typically measured in terms of compressive strength, which is the amount of force required to crush a concrete cylinder or cube of a certain size.

The standard size for concrete test specimens is a cylinder with a diameter of 6 inches and a height of 12 inches. The compressive strength of concrete is expressed in pounds per square inch (psi) or megapascals (MPa).

The strength of concrete depends on several factors, including the type of cement used, the water-cement ratio, the amount and type of aggregates used, the curing conditions, and the presence of additives.

The type of cement used can have a significant impact on the strength of concrete. For example, Portland cement is commonly used in the United States and has a compressive strength of around 7,000 to 10,000 psi after 28 days of curing. Other types of cement, such as high-strength Portland cement, can have compressive strengths of up to 14,000 psi.

What Affects Concrete Strength?

Water to cement ratio is another important factor that affects concrete strength.

The water-cement ratio is the ratio of the weight of water to the weight of cement in a concrete mix.

A higher water-cement ratio typically results in lower-strength concrete because excess water weakens the bonds between the cement and aggregates. The ideal water-cement ratio varies depending on the type of concrete and the environmental conditions.

Finally, additives can be used to improve the strength of concrete. Additives can be used to increase the workability of concrete, reduce its water-cement ratio, or accelerate its curing time.

Some additives, such as fly ash or silica fume, can also improve the strength of concrete by filling in the gaps between the cement and aggregates and increasing the density of the concrete.

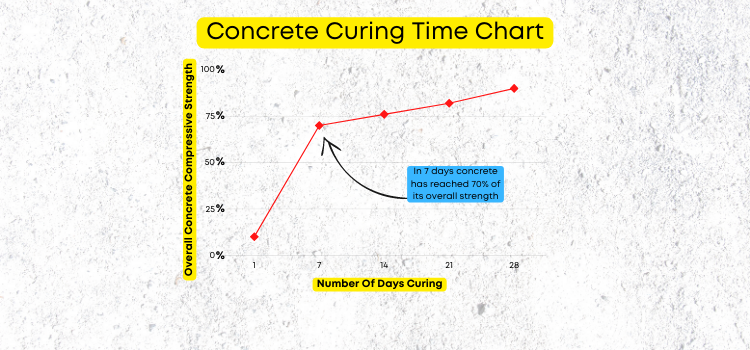

28 Day Concrete Strength Chart

Concrete strength charts are a useful tool for monitoring and predicting the strength development of concrete over time. In this blog, I have provided a short 28-day concrete strength chart that shows the expected strength of concrete at different ages.

The strength of concrete is measured in terms of its compressive strength, which is the ability of the concrete to resist compressive loads. The 28-day strength of concrete is often used as a reference point for assessing the quality of the concrete and its ability to meet design specifications.

Here is a typical 28-day concrete strength chart: ( View 28-day graph here )

| Age (days) | Compressive Strength (psi) |

|---|---|

| 1 | 1,000 – 2,000 |

| 3 | 2,500 – 3,000 |

| 7 | 4,000 – 5,000 |

| 14 | 5,000 – 6,000 |

| 21 | 6,000 – 7,000 |

| 28 | 6,500 – 8,500 |

The chart shows the expected compressive strength of concrete at different ages. For example, at one day old, the concrete will typically have a compressive strength of 1,000 to 2,000 psi, while at 28 days old, it will have a compressive strength of 6,500 to 8,500 psi.

It’s important to note that this chart is only a general guide, and the actual strength of concrete can vary depending on a variety of factors, including the mix design, curing conditions, and testing procedures.

Therefore, it’s essential to conduct proper testing to ensure that the concrete meets the required strength specifications.

How To Test Concrete Strength

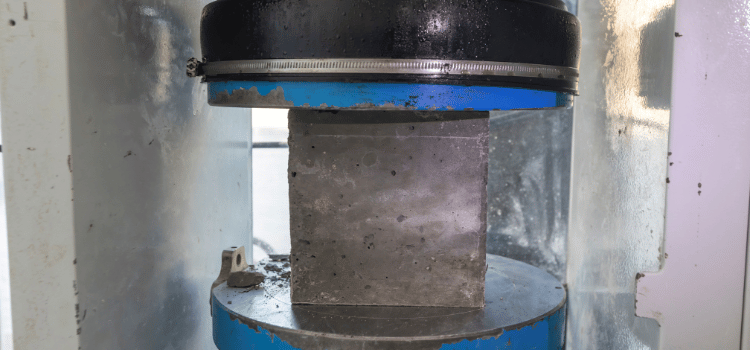

Testing the strength of concrete is a critical step in determining its quality and suitability for various applications.

In this blog, we will discuss how to test concrete strength and provide a general overview of the testing procedures.

Sampling and Specimen Preparation

The first step in testing concrete strength is to collect a sample of the concrete. This sample should be representative of the entire batch of concrete and should be taken in accordance with ASTM C172. After collecting the sample, it should be stored in a moist environment to prevent it from drying out.

Once the sample has been collected, it’s time to prepare test specimens. The most common type of test specimen is a cylindrical specimen with a diameter of 6 inches and a height of 12 inches. The specimen should be molded and cured in accordance with ASTM C31.

Compression Testing

Compression testing is the most commonly used method for testing the strength of concrete. In this test, the specimen is placed in a compression testing machine, and a compressive force is applied until the specimen fails.

The compressive strength of the specimen is calculated by dividing the maximum load by the cross-sectional area of the specimen. The test should be performed in accordance with ASTM C39, which specifies the loading rate, the age of the specimen, and the number of specimens to be tested.

Non-Destructive Testing

Non-destructive testing (NDT) is another method for testing the strength of concrete. NDT methods include ultrasonic testing, rebound hammer testing, and pull-out testing. These methods are used to estimate the strength of the concrete without damaging the structure.

NDT methods are useful when testing existing structures or when it’s not feasible to take samples from the structure. However, these methods are less accurate than compression testing and should be used in conjunction with other methods to ensure accurate results.

Testing the strength of concrete is a critical step in determining its quality and suitability for various applications.

Compression testing is the most commonly used method, but non-destructive testing methods can also be used. It’s important to follow standard testing procedures and to ensure that the samples are representative of the entire batch of concrete. Proper testing can help ensure that the concrete meets the required strength specifications and can help prevent costly failures.

Conclusion

In conclusion, concrete strength is a critical factor in determining the quality and suitability of concrete for various applications.

The compressive strength of concrete is commonly used as a reference point for assessing its quality, and the 28-day strength is often used as a benchmark for meeting design specifications.

Testing the strength of concrete is an essential step in ensuring its quality and suitability.

Compression testing is the most commonly used method, but non-destructive testing methods can also be used. It’s important to follow standard testing procedures, take representative samples, and ensure proper curing and testing conditions to ensure accurate results.

Proper testing can help prevent costly failures and ensure that the concrete meets the required strength specifications.

It’s important to work with qualified professionals and follow industry standards to ensure the quality and safety of concrete structures.

By understanding concrete strength and testing methods, we can ensure that the concrete structures we rely on are strong and durable.