Concrete knee boards are helpful, and multi-purpose, and make working on your knees pain-free and more enjoyable.

I have used concrete knee boards almost daily throughout my 15 years of concrete placing and finishing and I know, regardless of what you may be intending them for, you will not be disappointed and your knees will thank you getting a set.

Why Use Concrete Knee Boards?

Concrete knee boards of any kind are very beneficial for your knee’s health and can save you a lifelong world of trouble with your knees

As a concrete placer and finisher, we used these boards on a daily basis to help with all types of work including…

- Boxing and formwork.

- Trowel finishing concrete driveways and patios.

- Tidying up edges or pads that are needing attention before the concrete is able to be walked on.

- Foam knee boards are great for any kneeling activity like gardening, and are easy to move around.

Types Of Concrete Knee Boards

For concrete finishing, two types of concrete knee boards are ideal for you, your job, and your knees.

These Concrete knee boards are easy to use, make the job easier, and are ideal for almost every job!

The two main types of concrete knee boards are:

1: Steel slider knee boards.

2: Foam Padded Knee Boards.

What To Look For When Buying Concrete Knee Boards

You might not have thought so, but there are a few things to take note of if buying a set of concrete knee boards.

I have tried many brands of concrete knee boards over the years and only from experience have I learned what to look for when buying a set.

What To Look For In Concrete Knee Boards

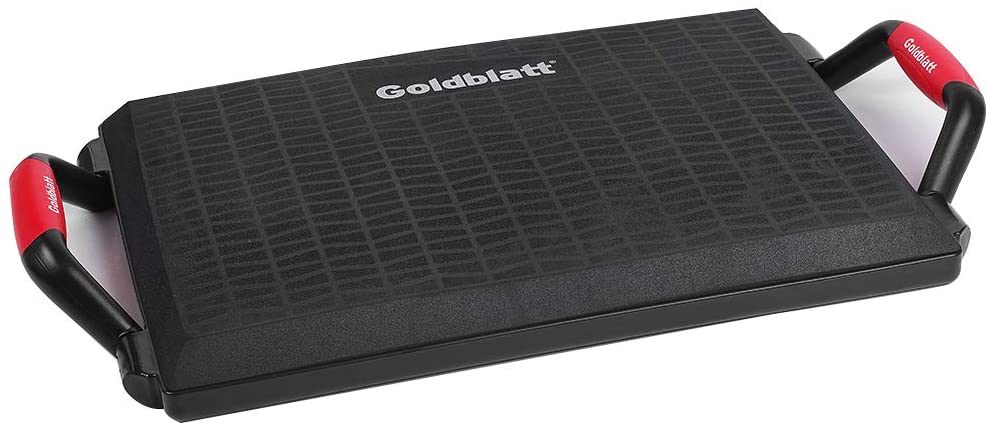

Foam Concrete Knee Boards

- Thickness of foam Padding: Over time the foam padding will squash and naturally wear thin. Make sure the foam is of good thickness and is not too soft, hard firm is better.

- Handles: Make sure the handles are strong and easy to grab/hold of.

- The glue holding the foam in: This one is a bit harder to test before buying but I know unbranded, unknown brands usually use cheap glue which always results in the foam padding falling out.

- Rounded edges: The plastic should have nice, rounded edges, and should not be square or sharp.

Sliding Concrete Knee Boards

- Weight: Sliding concrete knee boards can get heavy. Too heavy is not practical, but some find this ok and would rather heaver equipment. Check the overall weight.

- Knee Padding: The padding in the knee brace should be of decent thickness, and your knees should still be comfortable.

- Rounded edges: Make sure the edges of the boards are rounded and not square.

Cleaning Foam Concrete Knee Boards

Cleaning your knee boards is crucial for getting the most out of your knee boards for as long as possible.

When cleaning foam knee boards with water, try to avoid getting water under the foam. If it gets underneath and does not dry, the foam starts to smell, and will also help the foam break down.

Wash the underneath side only, and allow to dry.

Concrete will build up on the bottom of the boards if you do not wash them, and once concrete builds up underneath the board, this will start leaving an imprint on concrete, or worse, stick to concrete and chunks will lift out when you are lifting the kneeboard.

If this happens, use a scraping tool or a trowel edge to scrape clean again.

Homemade Concrete Kneeboards

If you are using concrete knee boards on a more than often basis I would strongly urge you to buy a set, however if you are only needing a knee board for a one-off use, then there are things we can use around the home to make you own homemade concrete kneeboards

I have personally used pollysterine chillybin lids, I have used small planks of timber, and on a small few occasions folded up cardboard.

Depending on your usage for them, the usability, weight, curved edges and comfort will still come into play.

The easiest homemade concrete knee boards in my opinion would have to be the polystyrene chilly bin lid.

How To Make Homemade Kneeboards

1: Find 1 or 2 polystyrene chilly bin lids. If they are thin, you can double or triple up to make thicker by stacking and gluing/taping them together.

If the are big in size you may want to cut them down. About 500 x 350mm will be good, but just what feels right for you.

2: Handles can be made by gluing string or thin rope onto the board.

Or…

Drill or poke 1 or 2 holes in about 50mm (2 inches) from the center of each end, after this, you can poke the string or rope through and tie a knot bigger than the hole so it will not pull back through.

Be sure to countersink the knot into the underside of the lid if you are using them on soft concrete, otherwise, the knots will leave imprints.

Concrete Knee Boards FAQ's

FAQ 1: Are concrete knee boards easy to use?

Answer: The foam concrete knee boards are straight forward and easy to use. The sliding concrete knee boards are easy to use but will take practice and getting used too.

FAQ 2: Where can we get concrete knee boards from?

Answer: You can buy concrete knee boards online from Amazon.com, they also have the largest variety.

FAQ 3: How long do the foam ones last?

Answer: Foam knee boards will last anywhere from 3 months to 1 year depending on use and care.

My Summary For Concrete Knee Boards

As I mentioned earlier, concrete knee boards are a knee saver. They make those crouching-down jobs enjoyable, not painful and are useable for all types of work.

I strongly recommend them.